Abstract

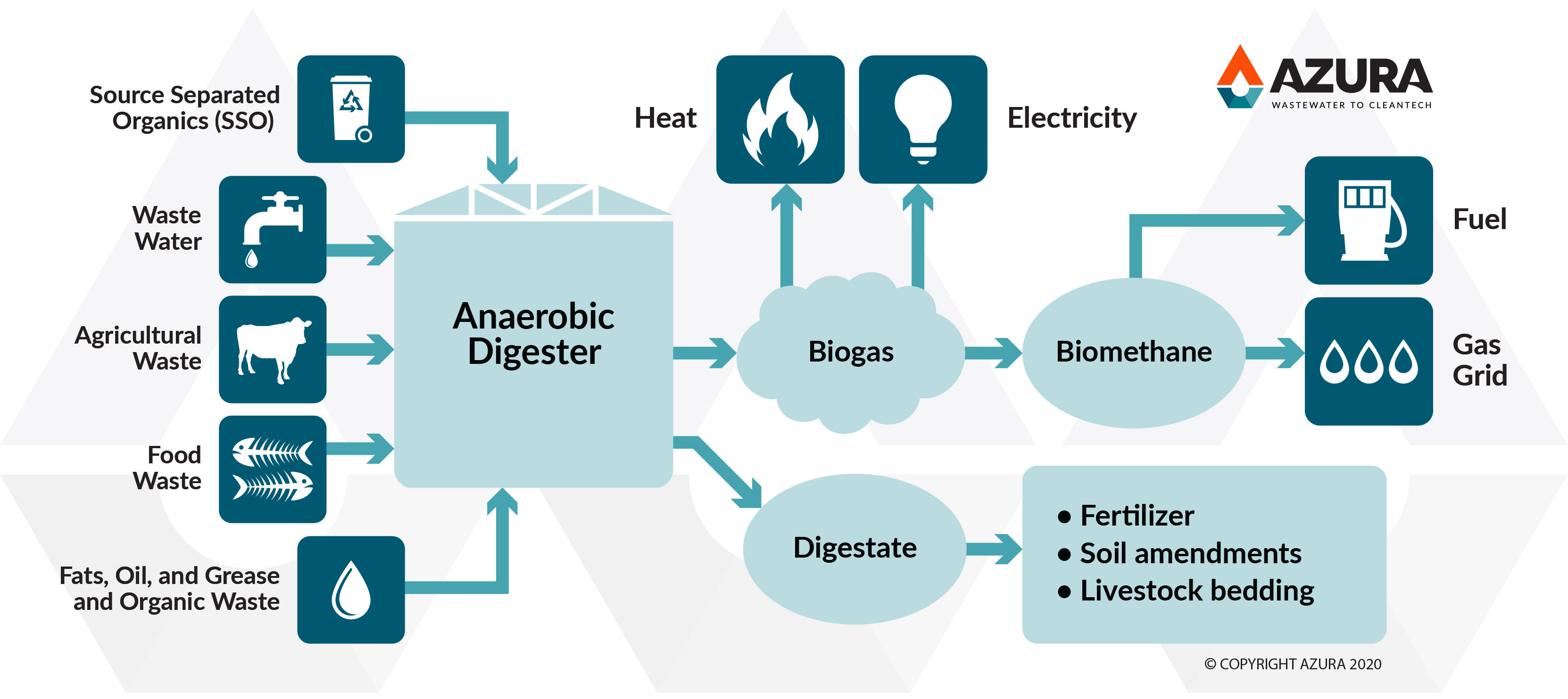

Anaerobic digestion (AD) is a simple process that has been occurring in nature for millions of years without human intervention. As people harness and intensify this process, we come to realize anaerobic digestion is a complex biological process that requires a great deal of nuance and subtlety to successful master and optimize its operation. In this article, we discuss the 10 most critical aspects of anaerobic digestion and how to make them run for the best outcome. In the vast majority of anaerobic digester, biogas, or renewable natural gas (RNG) projects, if these 10 criteria are met, the project will be a success.

1. Biology

Understanding the biological structure of anaerobic digestion processes is very important. The whole anaerobic digestion system is the culmination of many groups of microbes working in balance with each other. After large solids are broken down, the food waste or other feedstocks are broken down, in sequence, according to the following major phases:

- Hydrolysis: Large organic molecules are broken down into the smaller macromolecules

- Complex carbohydrates into simple sugars

- Proteins into amino acids

- Lipids into fatty acids

- Fermentation – acidogenesis: macromolecules are fermented into short-chain fatty acids, also called volatile fatty acids (VFAs)

- Fermentation – acetogenesis: the longer VFAs are then fermented to form acetic acid

- Methanogenesis: acetic acid is converted to methane

Each of these steps needs to be in balance with the others, just one step falling out of balance can lead to a downward spiral that eventually leads to digester failure.

2. Feedstocks

Just like humans, a digester’s diet is very important to its health and stability. The feedstocks going to the digester play a critical role in its performance and so, understanding the nature and variability of the feedstocks is of utmost importance. Important considerations and characteristics of feedstocks include:

- Feedstock source, frequency, reliability, and variability

- Flowability or workability

- Organic content and fuel value

- Relative biodegradability

- Nutritional content

- Contamination, plastics, non-digestible materials

- Toxic or inhibitory compounds

3. Water

Water is the vital medium for life. The microbes in an anaerobic digester live suspended in the water. The water also a provides a medium for the feedstocks to get to the cells.

Water also plays a mechanical role in the digester processes. Some feedstocks are very watery being 1%-10% dry solids, others are more sludge or cake-like at 20% dry solids, and some are bone-dry. The bone-dry feedstocks are typically agricultural residue streams. These residues need to be mixed in with watery feedstocks or with just straight water in order for them to flow and be workable or pumpable.

4. Temperature

Like all living organisms the microbes in anaerobic digesters have an ideal temperature for their metabolic functions. For mesophilic digesters, the ideal temperature is 35-37°C (95-98°F) and for thermophilic digesters, the ideal temperature is 50-55°C (122-130°F). Digesters are very sensitive to temperature changes, with any temperature change beyond 1°C (2°F) per day usually disrupting biogas production and leading to upsets if the temperature control is not stabilized.

Maintaining the digester temperature can prove challenging, particularly depending on the local climate. Cold-weather climates present heating challenges, most easily overcome by well-insulated tanks and equipment as well as a heating system rated to meet the heating demands of the coldest expected temperature and beyond. Very cold or frozen feedstocks also need to be considered in the facility design. Lower temperatures can also lead to mixing challenges, as feedstock fat, oil, and grease (FOG) materials will congeal, making the feedstocks more prone to plugging pipes and pumps and affect the mixing performance.

Hot weather can also create temperature problems when the digester can’t shed its excess heat and the biomass becomes over-heated. The AD process generates heat from the biological activity in the digester, the same way that people get warm when exercising. As most digesters have no active cooling, the only remedies are to add cool water, actively cool the digester through a chiller, or let the digester passively cool. So, biological heat generation should be considered and digester overheating avoided in hot climate areas.

5. pH, Alkalinity, and VFAs

Just like temperature, the digester biology also has an ideal pH range for their metabolic functions. Typically, complete-mixed anaerobic digesters operate with a pH between 7.2-7.6 as an ideal target, however, the digester biology can usually function well with a pH between 6.8-7.8. Some industrial waste digesters are stable operating at pH values in the 6.5 range or up as high as 8.2.

Alkalinity, composed of carbonates, bicarbonates, and hydroxides, is the buffer system in digesters that protects against acidification and keeps the pH stable. Before being converted to methane, organic molecules are fermented into volatile fatty acids (VFAs), which will lower the pH of the digester, if the alkalinity buffer is not sufficient.

The balance of VFAs, alkalinity, and pH are a very useful indicator of biological stability. Both the VFAs and alkalinity are commonly measured in a two-step titration test that can be performed on-site manually or with automatic titrators.

A well-fed digester with plenty of nutrients will generally have its VFAs, alkalinity, and pH reach a natural balance. However, if the digester becomes over-acidified and simply reducing or halting feed does not correct the pH, alkalinity may be added directly to the digester to correct this, usually in the form of magnesium hydroxide, lime, or baking soda.

6. Macronutrients

Nitrogen, phosphorus, and potassium are essential building blocks for biological growth. All organisms require these macronutrients to grow new cells. As a result, most food and organic wastes contain plentiful amounts of these macronutrients. The most common to be the limiting nutrient is phosphorus, and it may require additional supplements depending on the phosphorus content of the specific feedstocks. Many low-strength industrial wastewaters are short on phosphorus and thus require supplementation.

Conversely, nitrogen, in the form of ammonia, and potassium can be inhibitory to digester biology in high enough concentrations. Therefore, it is important to find the balance to keep the biology in the optimal range.

7. Minerals and Micronutrients

The anaerobic digester biology relies on several trace metals that play key roles in its metabolism. Metals like cobalt, molybdenum, iron, and nickel, are important for biogas production and without them, the digester performance will stagnate.

Most digesters, thanks to the nutrient content of their feedstocks, have plentiful micronutrients and operate very well. This includes digesters that take biosolids, manure, vegetable and fruit waste, and brewery wastes—all nutrient rich waste streams. However, many agricultural residues and high fat waste streams contain very little nutrients and will need to be co-digested with nutrient rich feedstock or they will require nutrient supplements.

8. Inhibition and Toxicity

Understanding the true source of one’s feedstocks is vital. Some feedstocks, particularly those from waste aggregators, may contain unknown compounds that are slowly inhibitory or outright toxic to digesters. Industrial sources of organic waste may also contain anti-bacterial cleaning agents, like sanitizers from a food factory, most of which are highly toxic to anaerobic digesters.

Opportunistic feedstocks may be especially troublesome, as they are not usually tested as extensively, and the operators have little data to act on when deciding whether to accept or reject the material. Even long-term industrial sources may change their operations, change their sanitizers, or change their wastewater treatment chemicals, which can all cause changes to the waste sent to digesters.

Buildups of inhibitory compounds such as salts or ammonia can also occur as a result of normal operation, for example, protein breakdown releases ammonia. These are generally slow changes and a build up of ammonia can be detected with regular monthly or quarterly testing.

9. Mixing and Agitation

As simple as it sounds, good mixing helps achieve good digestion. A well-mixed digestate has maximal contact between the biology and feedstocks.

Mixing also helps with mechanical functionality as well. Crust can form on the digestate surface and heavier solids can accumulate on the bottom, both of which create “dead-zones” in the digester, reducing the effective volume and performance. Vigorous mixing helps prevent or mitigate these solid buildups and reduce any downtime for digester clean-outs to remove built-up solids.

10. Contact Time

The nature of your feedstock can affect the type of anaerobic process that you use. Feedstocks that are slow to biodegrade require more contact time with the biology, requiring days or weeks to fully breakdown while some readily degradable materials can be degraded in a matter of hours.

High solids, slowly degradable feedstocks, such as FOG, complex vegetable waste, and many types of manure, typically are only suited for complete-mixed digesters with hydraulic residence times (HRTs) up to 30-40 days.

Municipal source separated organic (SSO) waste, sewage biosolids, more readily degraded food waste typically operate at HRTs in the 15 to 25 day range.

Feedstocks with low, mostly soluble organic content, can be treated with high-rate processes such as fluidized beds or granular sludge reactors that operate with HRT’s less than 24 hours usually closer to 6-8 hours. Some sugar wastewaters are treated in a few as a few hours. These high-rate processes are commonly used for single-source industrial wastewater treatment, such brewery, distillery, sugar processing, or fuel ethanol wastewaters, as well as other beverage manufacturing processes.

In Conclusion

Having a solid grasp of the 10 items listed above is the key to stable biology and smooth operation for anaerobic digesters. Maintaining good environmental conditions is the first step. A keen understanding of the feedstocks, their fuel value, nutrition content, and any potential contamination and toxicities is critical to keeping the biology happy and healthy.

Authors:

David Ellis, MASc., PEng., Principal Engineer

Michael Nelson, PhD, Process Analysis Lead

This article was first published on Biogas World

Related Articles

Ammonia Control Strategies

If lab testing indicates that your digestate might contain too much ammonia, what can you do? There a number of steps to reduce problematic gasses in an anaerobic digester. Read the full article.

Commonly Overlooked Reasons for Anaerobic Digester Failures

Based on more than 30 years experience with digester facilities, this article presents the top five commonly overlooked causes of digester failure so you can recognize and avoid these pitfalls. Read the full article.

Get Insights from the Bioprocess Experts Right to Your inbox

Sign up to the Discover Digesters Newsletter to access Azura’s best practices, field-tested advice, and insights into the anaerobic digestion & industrial wastewater treatment industries.

By submitting this form, you are consenting to receive marketing emails from: Azura Associates. You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact.