THE AZURA TEAM

Azura uses an associate business model as our organizational structure. This approach allows us to focus expertise where you need it most and not burden our clients with the costs of a large fixed overhead. We focus on the knowledge and experience of our associates in helping our clients and their projects. Each associate brings their own experience and expertise to the areas where they are subject matter experts.

Azura staff have developed deep connections with industry leaders and key personnel. This network is an integral part of the Azura intellectual portfolio as these friends and colleagues help expand our idea-base. We often find solutions to industry problems by taking insights from other sectors and creatively adapting and applying them to our client concerns.

Our associates have worked on assignments for numerous clients across most industrial sectors. We have had the good fortune to work on more than 300 client engagements across not only Canada and the USA, but also Europe, Africa, and South America. Many of our private client projects are in the following sectors: waste-to-energy, food & beverage, agriculture, and agri-food. We also extend our core expertise to support other professionals such as private law firms, the insurance industry, asset management firms, and the financial services sector.

Michael Nelson, PhD, MEng

Process Analysis Lead

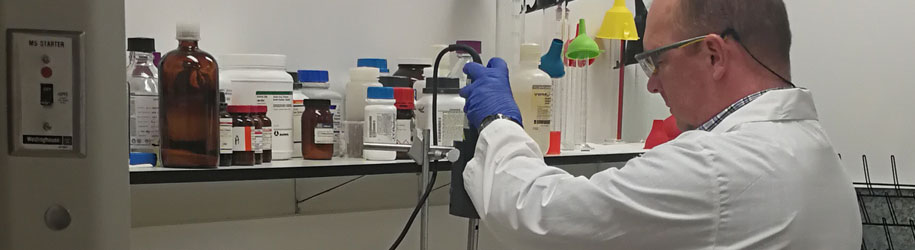

As Process Analysis Lead for Azura, Michael’s focus is on all the details. He manages sample collection, complex data analysis, and bioprocess modelling and interpretation for our clients. His work includes the development of Azura’s sample preparation and laboratory testing protocols for anaerobic digester feedstocks and digestate. One current area of research and development is a suite of advanced digester monitoring tools to support stable biogas production.

Michael completed his Engineering Science degree with an emphasis on Green Process Engineering and a Masters in Chemical Engineering from Western University in London, Ontario. Following this, he completed his PhD in Chemical and Biochemical Engineering through a joint program with both Western University and Tianjin University. The focus of his thesis was, “Commercialization of the Circulating Fluidized Bed Bioreactor for Municipal Wastewater Treatment.” His expertise is in the design of wastewater and anaerobic digestion treatment systems. His experience includes operating pilot-scale biological treatment research studies, bioprocess system and anaerobic digester modelling, and evaluating the biological treatment performance of both aerobic and anaerobic biological wastewater and waste-to-value systems.

Originally from Fort Frances, Ontario, Michael is pleased to now be living in the milder climate of Southern Ontario. Outside the office, Michael can be found rock climbing, cross-country skiing, fishing or hunting, and on more relaxing days, tending to his gardens.

James Arambarri, MASc

Optimization Lead

As Optimization Lead, James uses his expertise to help our clients to optimize their anaerobic digesters and industrial wastewater systems, with a special emphasis on biological treatment process debottlenecking. James also plays a key role in Azura’s technical due diligence, project risk management, and regulatory compliance work. James has developed advanced Risk Registry tools as part of our work with Owners and Investors in RNG, biogas, and biodigester decarbonization projects.

James completed his Environmental Engineering and Master of Applied Science degrees from the University of Guelph in Ontario. His research work investigated the use of electroflotation to treat high-strength industrial wastewater and helped him gain expertise in treating microbrewery wastes.

Building on his research work, James worked for several years with innovative wastewater treatment technologies for industrial and decentralized wastewater treatment. His work also included research and development of environmental remediation technologies.

When he is not in the office, James can often be found on a soccer-pitch or squash court. Growing up in Canada, Singapore, and the Middle East has inspired a love of travel and James particularly enjoys getting back to warm tropical waters for scuba diving!

Peter Quosai, MASc

Bioprocess Analyst

As Bioprocess Analyst, Peter brings his expertise in anaerobic biology, fermentation, and reactor design to Azura’s anaerobic digestion and industrial wastewater projects. Peter uses his expertise to optimize our clients’ anaerobic pretreatment and digester systems. He is also a key part of Azura’s work with high-strength and industrial wastewater systems, focusing on process debottlenecking, technical due diligence, and feasibility studies.

Peter completed his Biological Engineering degree from the University of Guelph and followed that with a Master’s in Civil and Environmental Engineering from the University of Waterloo in Ontario. No stranger to the waste-to-value mindset, his graduate research investigated acidogenic fermentation and anaerobic digestion for the production of short- and medium-chain fatty acids from food waste. This technology is being developed to recover more value and energy from food waste and create a pathway to sustainable bioplastic production.

When he is not in the office, Peter enjoys long trail runs and coaching developing distance runners with the Royal City Athletics Club. He also uses his fermentation knowledge at home, making his own hard apple cider.

Trisha Aldovino

Process Analyst

As a Process Analyst, Trisha focuses on process design and optimizing operational efficiencies across all projects undertaken by Azura. By harnessing her ability to distill complex technical ideas into understandable and actionable insights, she empowers clients with clearer communication and facilitates more effective decision-making.

Trisha completed her Chemical Engineering degree from the University of Waterloo with a specialization in Materials & Manufacturing. Her passion for creating a sustainable future was kindled during her research of membrane-based purification processes for more sustainable high purity ethanol production.

Dedicated to a growth mindset and diversifying her skills, she also thrived in the IT and tech domain. Trisha blends her experience in agile processes with her commitment to innovation to drive Azura’s performance to new heights.

Outside of the office you can find Trisha with a sketchbook and favorite black pen working on illustrations inspired by life. She also enjoys long walks and has recently taken up weight lifting.

FACILITIES

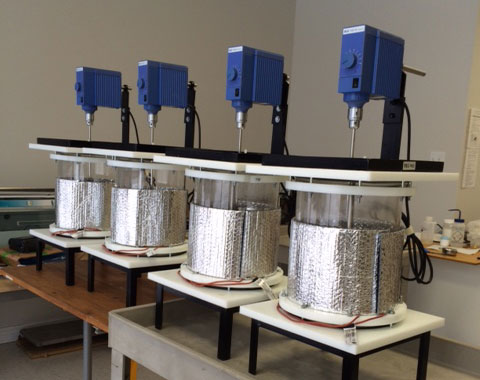

Azura extends the associate business model to include facilities. In addition to Azura’s modest testing area, we are able to leverage long-standing relationships within and across the scientific and engineering communities. These relationships allow us to make appropriate facilities available to suit any client needs.

For sample integrity and data quality reasons we prefer to undertake treatability testing and pilot trials at client facilities—close to the processes generating the material being evaluated. If required, we use our broad network of facilities, at both private and university-based laboratories, to conduct short- and long-term evaluations. From one-day wastewater genetic testing trials to months-long anaerobic digestion treatability tests, Azura is able to tap into the right resource at the right time to drive our client’s business solutions.