The most expensive part of an anaerobic digester are often the corrosion resistant tanks that are needed to hold massive volumes of digestate at constant temperature. Since digester volume is one of the most valuable assets of a plant because that determines how much you can feed – preserving and measuring digester volume might just be one of the most valuable methods for digester optimization. There are three ways that digesters often lose working volume and three ways for determining if your working volume has been lost.

Working Volume: The True Capacity of a Digester

The working volume of a digester is the liquid-filled space where microbes can glide through and convert organic matter to methane. While design values are based on total tank dimensions, real working volume changes over time as

- grit (sand, silt, bone, shells, plastics, and heavy inert materials) accumulates at the bottom,

- floating crust or foam layers (fibrous mats, fats, and buoyant plastics) build up at the surface, and

- poor mixing causes dead zones and “short circuiting”, where microbes are trapped in one part of the tank instead of reaching all of the organics, preventing much of it from becoming gas.

A reduction in working volume effectively shortens the hydraulic retention time (HRT) and increases the organic loading rate (OLR), stressing microbial communities and limiting digestion performance.

Example: A tank designed for 20 days HRT may only achieve 15–17 days if 15–25% of its capacity is lost to grit or crust.

Grit

Even in well-designed systems, grit accumulates gradually. Grit consists of sand, glass, and bone that are common in many food waste feedstocks as well as undegradable organics such as wood and dense plastics. When these materials settle to the bottom of the tank, they create a dead zone where the organics can no longer reach.

The best management technologies either remove grit before it reaches the digester or actively remove grit from the bottom of the digester without requiring cleanout.

If you are interested in learning more check out our video on Grit.

Crust and Foam

The constant generation of biogas in a digester carries floating material and fiber up to the surface of the digester. If the surface is not broken up and the that floating material does not break down quickly enough, then a crust or fat layer will form in the digester. As material continues to enter the digester, the crust layer grows upward. Fats and proteins act like a glue that strengthens the crust layers, thus making it solid. To ultrasound level sensors at the top of tank, it looks like the digester is filling up. But in reality, the working volume is decreasing. The digester is filling up with a solid crust instead of liquid. That crust can damage equipment at the top of the digester if it continues to grow.

Similarly in digesters designed with little freeboard, operators sensibly lower the operating level in foaming events to prevent spills and damage to equipment. What is often not factored in is the reduction in working volume and feeding capacity that results from this change.

If you are interested in learning more about foam check our foam article.

Short Circuiting

Although hard to visualize, a digester’s working volume can decrease even without a layer grit or crust. Poor mixing can cause short circuiting, which reduces working volume. It is rare for a mixing system to be designed badly enough that it causes short circuiting. However, short circuiting can occur when one or more mixers are broken. When mixers break, “dead zones” where nothing flows starts forming around the mixer. Waste then takes a shortcut from inlet to outlet instead of mixing. This channel can carry undigested organics straight through a digester without converting them to gas. This is the hardest problem to detect and should be addressed by maintaining mixing according to design for best performance.

Strategies for Maintaining Optimal Conditions

- Routine monitoring: of OLR and gas yields to identify unexplained losses in performance.

- Crude stick test methods: In some cases, the level of grit in a tank can be estimated by lowering a long pole down a maintenance hatch – use appropriate PPE as there will be biogas and hydrogen sulfide present – to see if the bottom of the digester if filled with material. The same crude methods can be used for a crust layer.

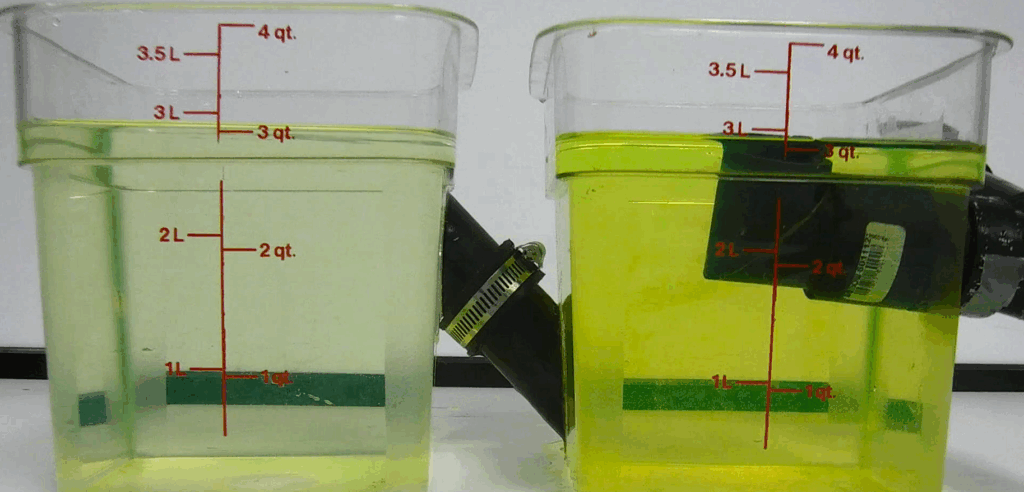

- Tracer studies: A tracer study can be performed by adding a spike of a detectable soluble and inert chemical to the digester and recording how the concentration changes in the outlet over time. The speed that the concentration changes can be used to calculate the working volume. Tracer studies are the only way to accurately determine if short circuiting is preventing a digester from achieving nameplate capacity.

Anaerobic digesters are dynamic systems where biological performance is inseparable from physical constraints. True optimization requires not only feeding and mixing strategies, but also preservation of working volume through periodic estimates of working volume and controlling grit, crust, foam and mixing. By maintaining stable HRT and OLR, operators can safeguard microbial activity, extend asset lifespan, and maximize renewable energy production.

*An abridged version of this article was first published in the Efficiency Issue of Biogas World’s Magazine.

Related Articles

Effective Grit Management in Anaerobic Digester Systems Starts with Testing

Grit is the silent saboteur of anaerobic digestion systems. Though it often makes up less than half of 1% of a feedstock by weight, grit can cause outsized problems.

Read the full article.

Commonly Overlooked Reasons for Anaerobic Digester Failures

Based on more than 30 years experience with digester facilities, this article presents the top five commonly overlooked causes of digester failure so you can recognize and avoid these pitfalls. Read the full article.

Get Insights from the Bioprocess Experts Right to Your inbox

Sign up to the Discover Digesters Newsletter to access Azura’s best practices, field-tested advice, and insights into the anaerobic digestion & industrial wastewater treatment industries.

By submitting this form, you are consenting to receive marketing emails from: Azura Associates. You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact.