Is your biodigester making less RNG than estimated during the feasibility assessment? One common cause is a phenomenon that Azura calls SLAC – Solids Loss on Aging and Collection. In this video Azura’s Principal Engineer, Dave Ellis explains how despite the best efforts of calculation, real-life fuel value can be much lower! Initial calculations use estimates and assumptions that don’t account for the feedstock’s age and collection practices.

Prefer to read? Check out the article below to better understand how feedstock management practices are key to getting the most value into the digester and maximizing your fuel potential.

The #1 Thing People Get Wrong When Assessing Biogas Project Viability

When making initial calculations, biomethane potential (BMP) is often much higher on paper than in real life. Let’s walk through an example to see why this happens.

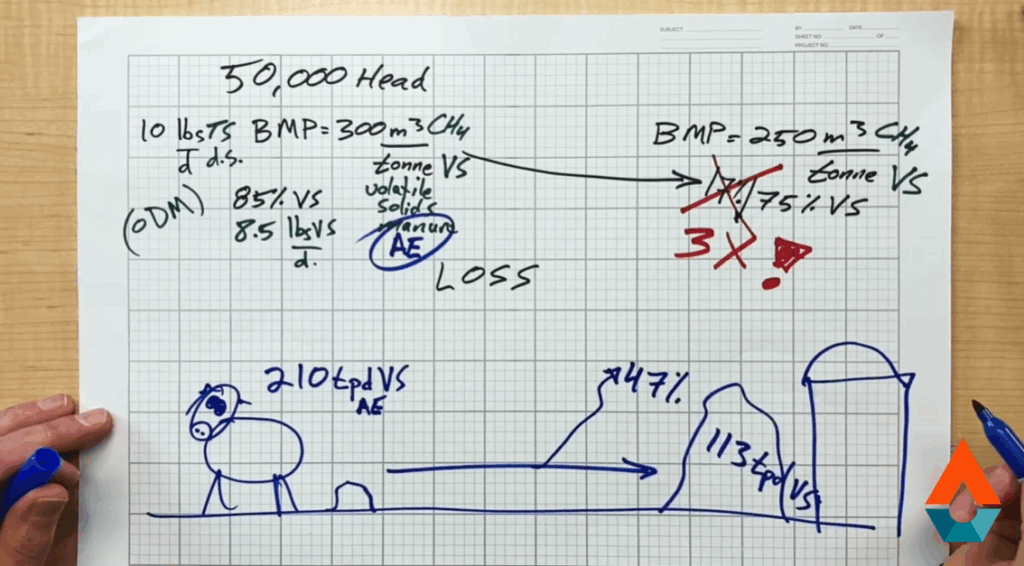

In this project we have a dairy farm in the 50,000 head range.

Using textbook numbers, we would expect approximately 10lb per day of manure solids excreted per animal which would be 250 tons per day of manure solids with the biomethane potential of approximately 300 cubic meters of methane per ton of volatile solids. With volatile solids at 85%, depending on the RNG value, this could mean $12 million or more in RNG revenue alone. Sounds like a very feasible project.

The next step would be to collect samples of the manure and have it tested for biomethane potential. The lab sends back real numbers with biomethane potential at 250 cubic meters of methane per ton of solids and 75% volatile solids. It looks like the methane yield drop was only 17%, unfortunately, this number is not correct. In reality, this project would be losing more than three times that amount of biogas!

SLAC – Solids Loss on Aging and Collection

Textbook values look at the fuel potential of manure as excreted. For example, 50,000 head of dairy cows producing 10lbs per day of total solids or 8.5lbs per day of volatile solids works out to about 210 tons per day of volatile solids.

In real life though, by the time the manure gets to the digester (or is sampled) and the volatile solids has dropped from 85% to 75% VS, you can be down from 210 tons per day to 113 tons of volatile solids, which is a 47% loss.

What happened? Aging and Collection.

Organic waste biodegrades every second of every day from as soon as it leaves the animal. Manure is full of fresh healthy bacteria, it’s warm, it biodegrades, and it continues to biodegrade right until the moment it goes in the digester, where it still biodegrades, except you’re able to capture the gas.

Collection is what is needed to get the manure from the animal to the digester. Whether it’s a water wash system, chain scraper alley, or bucket loaders, collection methods and how often you collect your manure matters quite a lot.

As manure sits on the yard or in the corral it’s aging. If you scrape the corral every two weeks, some of that manure is two weeks old, and some of that manure might only be two hours old, depending on when the last animal was through there.

Solids are lost that whole time, through the aging and collection process, which is what we call SLAC. Understanding the SLAC in your process is critical to understanding what’s going on, and if your project is going to going to reach it’s potential. In this example you’re losing almost half your money by not accounting for SLAC. You’re not getting the expected RNG value of approximately $30,000 per day, instead you’re only getting $15,000 per day.

Maximize Gas Production and Revenue for Your Biogas Project by Minimizing SLAC

SLAC is not just for manure, it applies to all organic material such as food waste, source separated organics (SSO), and the organic fraction of municipal solid waste (OFMSW). Anywhere the organic material is out in nature it has an opportunity to be breaking down. The key to minimizing SLAC is feedstock management.

As temperatures rise, the digestion process will accelerate. This means that in the summer months or in a warm climate, manure and organic waste need to be moved into the digester faster to capture as much methane as possible. In the winter, collection can be slower as frozen feedstock will break down much more slowly in the colder temperatures.

Seasonal feedstock management is an easy opportunity to get more fuel into your digester. Before this material breaks down, you’re able to take advantage of knowing about SLAC and harvest the most fuel value.

When to Assess Feedstocks for SLAC?

Understanding fuel value and where it could be lost will give you the insights to get the most gas production and revenue for your project. Assessing for SLAC can happen during:

- Feedstock evaluation

- Project Development Due Diligence

- Due Diligence on Property Transactions

- FEL-0 or other of Project Development Work.

Understanding the SLAC in your project is a critical component of managing your overall digester financial plan.

Want to better understand SLAC in your feedstock? Contact Azura today.

Related Articles

Top 10 Things to Make Your Digester Biology Happy

Anaerobic digestion is a complex biological process that requires a great deal of nuance and subtlety to optimize its operation. This article looks at the 10 most critical aspects of AD and how to make them run for the best outcome. Read the full article.

Digester Startup and Commissioning

Digester biology is most sensitive and fragile during startup and commissioning (S&C). This article looks at 5 key considerations that are often overlooked during S&C of anaerobic digesters. Read the full article.

Get Insights from the Bioprocess Experts Right to Your inbox

Sign up to the Discover Digesters Newsletter to access Azura’s best practices, field-tested advice, and insights into the anaerobic digestion & industrial wastewater treatment industries.

By submitting this form, you are consenting to receive marketing emails from: Azura Associates. You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact.