Grit is the silent saboteur of anaerobic digestion systems. Though it often makes up less than half of 1% of a feedstock by weight, grit can cause outsized problems — from equipment wear and abrasion and reduced digester capacity to costly maintenance and unplanned shutdowns. Yet despite its impact, grit is rarely well understood or systematically characterized.

Knowing which particles in a feedstock will settle as grit is essential for designing effective removal systems and optimizing digester performance. Grit characterization studies offer critical insights that help:

- Developers select the right technology for the job,

- Facility owners and managers plan financially for cleanouts, and

- Technology vendors demonstrate the effectiveness of their systems.

At Azura Associates, we frequently analyze feedstock samples to assess their impact on commercial anaerobic digesters. We determine whether they are toxic or nutritious, digestible or recalcitrant — typically using 4 to 40 kg of feedstock. Even heavily contaminated samples may contain only 4 g of grit per kg of feedstock — a small amount that, over time, can represent a substantial cumulative load. In high-solids feedstocks, like curbside organics (SSOs), manually compositing a representative sample is difficult due to the material’s density and heterogeneity. To address these problems, there needs to be a reliable, repeatable method to characterize grit in an anaerobic digester feedstock, irrespective of what form the samples come in.

The Quest for a Reliable Grit Test

There are several existing grit characterization methods from sectors including wastewater treatment, manure management, waste treatment, and food processing. Standards such as those from the Water Environment Federation (WEF) provide guidance for wastewater but are often inapplicable to more complex feedstocks. For example, manure systems often use sand as livestock bedding, which require different sampling and characterization approaches compared to wastewater, food waste, or source separated organics (SSOs).

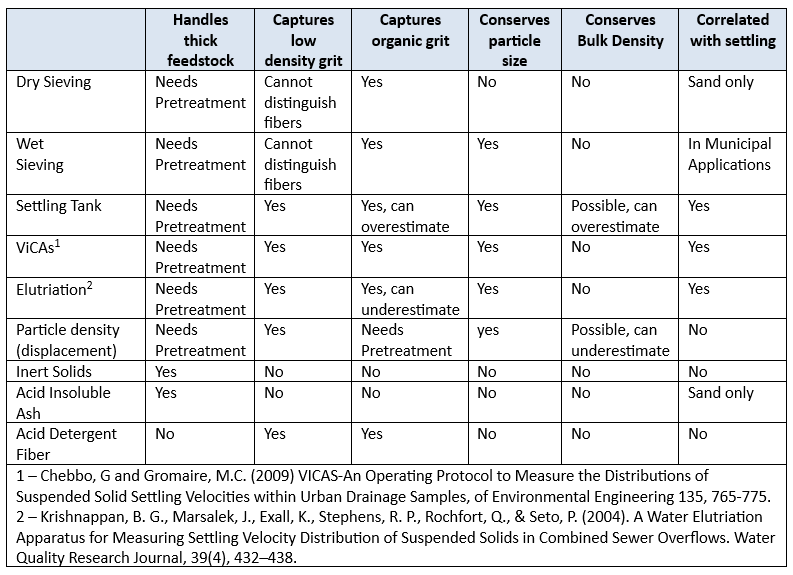

When investigating different grit testing methods, we compared following criteria:

- Compatibility with feedstocks of varying solids content (from <1% to >15% dry solids),

- Ability to detect low-density particles (~1.2 g/cm³),

- Capture of both organic and inorganic grit,

- Preservation of grit particle size,

- Estimation of volumetric, not just mass, accumulation, and

- Correlation with actual settling behavior in real full-scale anaerobic digesters.

Comparison of Existing Methods

The first six methods mentioned are used in the analysis of grit in sewage during the design of municipal wastewater treatment plants. These plants have large volume and dilute flows, therefore, to capture a large, settled grit sample, a fraction of the sewage stream is passed through a small settling tank and then characterized using sieving and settling tests. To use these methods for high solids feedstocks the feedstock needs to first be diluted and possibly prefiltered so that grit does not get held in suspension by fibers or gels. These pretreatments affect the results of the grit test and add cost to the method.

The final three methods are manure analysis techniques that can be performed on dry or wet samples. Each of these methods can alter the characteristics of the grit and therefore can only be used for quantifying grit load rather that characterising to design grit removal systems. The methods are fast, can be performed with limited lab resources, and require minimal pretreatment, making them relatively inexpensive and a good option for screening many samples to understand feedstock variability.

Developing a New Test

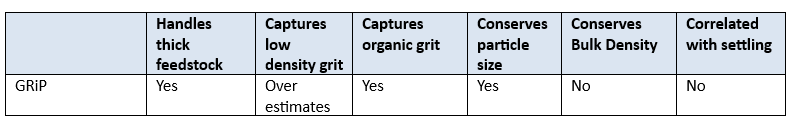

Looking at the existing methods, there appeared to be gaps in tests that could be consistently applied against a wide range of anaerobic digester feedstocks. To address these anaerobic digester feedstock testing gaps, Azura developed the Grit Risk Profile (GRiP) — a novel test designed for the specific challenges of anaerobic digestion systems. Drawing from diverse sectors, we created a methodology to accurately characterize grit across a wide range of feedstocks.

Key steps of the GRiP test include:

- Sampling — Guidelines for representative sampling from manure and food waste digesters.

- Fractionation — Separation of grit based on settling time.

- Characterization — Analysis of particle density (displacement), size (image processing), and composition (chemical methods).

In the sampling step, grit samples were collected directly from the separated grit from either grit removal systems or during digester clean outs. When collecting samples of raw feedstock, it is recommended to collect at least 10L of feedstock to generate a representative grit sample.

In the fractionation step, sequential settling tanks separate grit into several fractions based on their settling time. Fractions include:

- Fast-Settling Grit: >1.2 mm, includes coarse sand, gravel, and large organics; settles in poorly mixed tanks.

- Sand-Equivalent Grit: 0.6–1.2 mm; likely to accumulate without dedicated grit removal.

- Slow-Settling Grit: 0.1–0.6 mm; remains suspended in well-mixed digesters, but settles in low-solids or poorly mixed systems.

- Settleable Fines: <90 µm; likely to remain suspended and may include digestible organics, which should be retained for biogas production. These likely cannot be removed without also removing organics that can be digested. The retention of these organics for digestion and biogas production can be an objective of the grit handling system and digester mixer design.

In the characterisation step, wet grit samples were collected and drained. The wet, drained, grit was weighed. The weighed grit was then added to a graduated cylinder partially filled with water to measure the bulk density and wet particle density. The weighed grit was then dried.

Testing the Performance

To validate the GRiP test, the team conducted a series of experiments using a sequential settling tank system designed to capture and characterize the four target grit fractions. We performed calibration tests with sieved sand samples of known sizes and compared the results with grit collected from operating digesters accepting industrial food waste and source separated organics (SSOs).

The validation tests showed promising results, with the Azura GRiP method effectively differentiating grit fractions based on sand-equivalent size. However, the team also identified areas for improvement. The mixing energies used in the test apparatus needed to be correlated with real-world digester conditions to ensure accurate representation of grit behavior in actual full-scale anaerobic digester systems.

Evaluating the Method

We critically evaluated the GRiP method against the previously established criteria. While the GRiP test provided valuable insights into grit accumulation rates and helped optimize grit removal strategies, it was clear that further refinement was necessary.

Ultimately, the choice of grit test should be guided by the feedstock’s characteristics and the operational goals of the facility. For municipal wastewater and dilute streams, large samples are often settled in overflow settlers then characterized by traditional sieving and settling tests. For high solids manure samples, physical tests such as the acid insoluble ash test can give fast and inexpensive results for many samples. For high-solids, heterogeneous feedstocks, such as mechanically sorted organic fraction of municipal solid waste (OFMSW) or organics collected from curbside source separated organics (SSO) programs, a more nuanced approach is essential to accurately assess grit risk and inform system design. With ongoing development, GRiP promises to become a robust, standardized tool that helps developers, operators, and technology providers better manage grit — and the costs that come with it.

The test, as designed, captures organics in the final quiescent tank and the fractionation changes the bulk density of each fraction biasing any conclusions made about the bulk density that the combined mix of grit will take up in the digester. The mixing energies in the test are also much higher than we would expect to see in a digester and the grit fractionation is not as precise as we would like it. High mixing energies will keep more small particles in suspension and potentially wash out particles that could settle in real digesters – underestimating the total grit mass in a sample. For these reasons, the test is still under development, but with some hard work and grit we will soon be able to offer a test that is faster and better suited to food waste and complex feedstocks.

Conclusion

Effectively managing grit in anaerobic digestion systems begins with understanding the nature of the feedstock — and selecting the right grit characterization method accordingly. As this review shows, no single test meets all the criteria for all feedstocks. Traditional methods like dry and wet sieving are useful for simple, low-solids streams but fall short when applied to heterogeneous, high-solids materials like food waste, source separated organics, or manure. Settling-based methods such as ViCAs and elutriation offer better correlation with real-world grit behavior but require pretreatment and may overestimate the organic grit content.

The GRiP test, developed by Azura Associates, represents a significant step forward. It is uniquely designed to handle thick, complex feedstocks and captures a broad range of grit types, while preserving particle size and settling characteristics. However, as our evaluation shows, even GRiP has limitations: it may underestimate grit due to high mixing energies and the bulk density measurements are biased to overestimate combined grit volume. These challenges underscore the complexity of grit behavior in digesters and the need for continued refinement.

This article first appeared in the Environmental Science & Engineering Magazine.

Related Articles

Top 10 Things to Make Your Digester Biology Happy

Anaerobic digestion is a complex biological process that requires a great deal of nuance and subtlety to optimize its operation. This article looks at the 10 most critical aspects of AD and how to make them run for the best outcome. Read the full article.

Commonly Overlooked Reasons for Anaerobic Digester Failures

Based on more than 30 years experience with digester facilities, this article presents the top five commonly overlooked causes of digester failure so you can recognize and avoid these pitfalls. Read the full article.

Get Insights from the Bioprocess Experts Right to Your inbox

Sign up to the Discover Digesters Newsletter to access Azura’s best practices, field-tested advice, and insights into the anaerobic digestion & industrial wastewater treatment industries.

By submitting this form, you are consenting to receive marketing emails from: Azura Associates. You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact.