If you’ve worked at a biogas plant long enough, chances are you’ve encountered a foaming incident. Whether in the feedstock reception tanks or the digester itself, once foaming is spotted, it’s important to identify the root cause and plan how to prevent this from happening again. However, when jumping into action, it’s too easy to overlook both the immediate, and longer term, safety risks associated with a foaming event.

Foaming can pose serious environmental and safety hazards at a biodigester facility.

Operator Safety Risk:

Foam creates an obvious slip, trip, and fall risk, but there are also biohazards that are not as apparent. Under normal operating conditions, biogas is generated inside the digester and bubbles through the bulk digestate before releasing and into the digester headspace.

Feedstock foaming can be particularly risky as the causes and risks may be less obvious. During a digester foaming event, the process of gas bubbles forming and ‘popping’ becomes disrupted. Foam is inherently laden with hazardous gases and can create an unpredictable and high-risk environment for operators.

Before cleaning up any foaming event, operators should assess the safety aspects of the situation. First, take a few minutes to identify the potential risks and ask yourself the following:

- Am I wearing a biogas monitoring device?

- Am I working alone?

- Do I have proper PPE in case of slip, trip, or fall on a slick, foam affected surface? Feedstock foam can be exceptionally slippery, so extra caution is required.

Safety Equipment:

An unexpected foaming event can seriously impact the safe operation of a digester site. Depending on where it forms, digester foam can damage a wide range of biogas safety equipment. At Azura, we’ve seen foam impact:

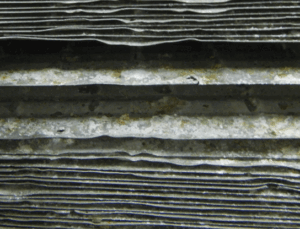

- Flame Arresters – Foam can partially plug flame arrestors, causing overpressure in the gas storage domes or reduce the arresting ability that prevents flame burnback, increasing the risk of fire or explosion.

- Pressure Vacuum Relief Valves (PVRVs)– Foam can also clog and foul these safety valves, preventing proper pressure relief and potentially lead to over-pressurization or vacuum conditions inside the feed tank, digester, or biogas piping.

- Emergency Flare – Foam entering the biogas piping can make it all the way to the biogas flare line, preventing or inhibiting safe operation of the flare, resulting in venting of biogas.

The risks aren’t limited to these devices. Foam can also damage important instrumentation, foul hydrogen sulfide (H2S) scrubbers, flood condensate traps, and damage expensive RNG upgrading equipment, all in addition to the physical hazards.

*This article was first published in the Safety Issue of Biogas World’s Magazine.

Related Articles

Why Is There Foam in My Digester?

Foam is a messy, sticky, and smelly problem in biodigesters. But why does foam form in an anaerobic digester in the first place? Read the full article.

Effectively Ensuring Safety in Biogas Facilities

Learn about five key categories of safety hazards and four hazard control methods within a biogas facility to better protect employees, the surrounding community, and our environment. Read the full article.

Get Insights from the Bioprocess Experts Right to Your inbox

Sign up to the Discover Digesters Newsletter to access Azura’s best practices, field-tested advice, and insights into the anaerobic digestion & industrial wastewater treatment industries.

By submitting this form, you are consenting to receive marketing emails from: Azura Associates. You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact.