Authors: David Ellis, Principal Engineer and Peter Quosai, Bioprocess Analyst

Introduction to Anaerobic Codigestion

The only currently established, potentially carbon-negative fuel in the world is energy produced from waste. As we seek to reduce our carbon footprint, codigesting food waste at sewage treatment plants presents an excellent opportunity to maximize existing resources and create a more sustainable future.

Codigestion of food waste is a process that blends waste materials from different sources–for example, food waste and sewage waste–together inside an anaerobic digester to produce biogas and Renewable Natural Gas (RNG).

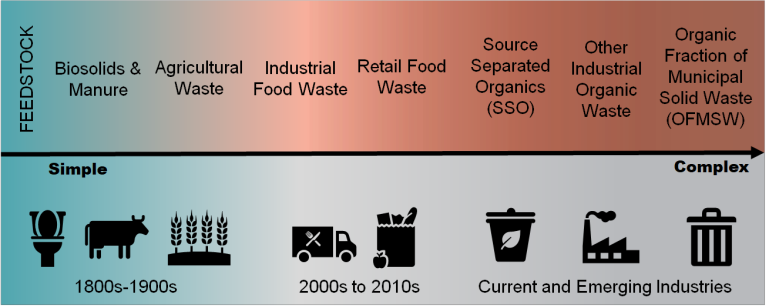

That biodegradable waste material can come from a variety of sources, including:

- Agricultural Waste from farm operations,

- Industrial Food Waste from your local apple pie factory or other food processors,

- Retail Food Waste, such as bruised grocery store fruit,

- Source Separated Organics (SSO) from your city’s curbside green bin program, and

- Organic Fraction of Municipal Solid Waste (OFMSW), which is produced by extracting food and other biodegradable waste out of household domestic garbage.

Without engineered anaerobic digestion facilities, much of this food and organic waste would wind up in manure pits or landfills and break down. This would still result in the production of biogas containing methane, except, that methane would be emitted into the environment, rather than captured and repurposed as energy.

When WRRFs accept organic waste for codigestion, the resulting biogas has a significantly lower Carbon Intensity (CI) score. This lower CI score considers the improved carbon footprint of the biogas and considers the landfill methane emissions that are avoided by diverting the waste to an engineered digester system.

Codigestion of food waste at Water Resource Recovery Facilities (WRRFs) is a promising solution to not only help WRRFs save on energy costs but to generate more energy, all while keeping our water clean and maximizing the use of existing assets.

Capturing Methane

The release of methane into nature should be avoided since it is a greenhouse gas more than 80x more potent than carbon dioxide over a 20-year timespan.

Historic U.S. Environmental Protection Agency (US EPA) estimates from the early 2000s indicated that landfill capture managed to get 60 to 90% of the methane produced. However, more recent research has shown that most landfill collection systems capture less than half of the methane they produce.

Conversely, producing methane in an engineered environment, like at a WRRF, allows for nearly complete methane capture. Once the biogas is produced, it can be burned in a cogeneration engine to produce heat and electricity to power the WRRF. Alternatively, the biogas can be purified to produce biomethane, which is then compressed to produce RNG. RNG has the same composition as traditional pipeline natural gas but has a much smaller carbon footprint.

RNG can be added to the current natural gas grid for use anywhere it is needed. One of the great things about the Ontario natural gas grid is its storage ability. We have enough natural gas storage in Ontario to power the entire province for months, even during peak winter demands if needed.

As long as people continue to prepare and consume food, food waste will be produced. This waste can then be transformed into biogas and RNG, making them clean and sustainable renewable fuels.

The Business Case for Codigestion

There are three key benefits for a municipal sewage treatment plant considering codigesting sewage solids with food waste:

- Revenue Generation,

- Waste Management, and

- Increased Energy Production.

Revenue Generation

Codigestion provides new revenue streams for existing anaerobic digestion facilities. Facilities can generate revenue from 1) the feedstock, in the form of a tip fee, 2) from the produced biogas itself, and 3) from carbon offsets from avoided emissions. Tip fees are charged on a dollar-per-tonne of waste basis to cover the cost of receiving and processing the waste. Just as landfills charge tipping fees, sewage treatment plants can do the same.

The lower CI value of the biogas produced incentivizes facilities to refine it into renewable natural gas, which can be injected into the natural gas grid or used as a clean transportation fuel. RNG fetches a premium price compared to natural gas, as the gas molecules can be sold in addition to the green attributes tied to avoided emissions from the digestion process.

By capturing methane that otherwise would have been released into the atmosphere (i.e., organic waste breaking down in a landfill), codigestion supports the generation of carbon offsets and provides another source of revenue for digester owners through either voluntary or regulated carbon markets.

Waste Management

Food waste is a significant issue in many cities. In Ontario, landfills are expected to be at capacity in less than 10 years.[1] It can take years (sometimes more than 10) to get all the permits and approval to build a new landfill, so timing is critical.

Food waste decomposing in landfills releases methane to the atmosphere, toxic leachate to wastewater treatment systems, and traps nutrients like phosphorus and nitrogen away from natural systems. Even when finished, landfills are generating methane they cannot capture as well as an anaerobic digester.

By codigesting food waste with sewage solids, municipalities can divert food waste from landfills, reduce landfill usage and the associated greenhouse gas (GHG) emissions, and can even extend the lifespan of landfills. Currently, Canada is only using 14% of the readily available biodegradable waste-also known as ‘feedstock’ for RNG[2] which leaves enormous potential to divert waste and create renewable fuel.

Increased Energy Production

Many sewage treatment plants are currently producing biogas because they already have an anaerobic digester. The anaerobic digesters at these WRRFs are often designed for a future population, resulting in a facility that is oversized for today’s needs.

Codigesting food waste can help increase the biogas production and maximize the utility of these existing assets with fewer energy costs. Food waste is also rich in different nutrients and high in fuel value, which can help the digester perform more efficiently than if it were processing sewage waste alone. The increased energy production can offset the high energy demands of WRRF operations and help municipalities achieve sustainability targets.

Assessing Adoption

To successfully introduce anaerobic codigestion for biogas and RNG production, these systems need to be both biologically and economically sustainable. When assessing an opportunity, stakeholders need to take a close look at the details. Questions to consider include:

- What biochemical benefits does the feedstock offer?

- What’s the fuel value of the feedstock available in the local area?

- How far does the feedstock need to be trucked?

- How much will the feedstock change seasonally?

- How will accepting new feedstock affect plant operations?

- Is there a risk that a feedstock may compromise the digester biology?

- Does the feedstock put us at higher risk for operational challenges such as foam, plastics, or grit?

When considering adopting codigestion, take on the mindset of someone farming as opposed to someone building a machine. Successful biogas production requires a long-term view of nutrition and balancing biology. If you focus on growing good biomass and feeding good feedstock, you can’t help but get great biogas out of the system and excellent RNG.

Evaluating Feedstocks for Codigestion

When evaluating potential feedstocks, anaerobic digestion experts start with a quick qualitative screen. We ask questions like:

- Is the material from a source that we would expect to be biodegradable?

- Did it start as a food or an agricultural material?

- What goes on inside the farm or factory where this waste is made?

Once it passes that first qualitative screen, the big number to look at is the fuel value. How much fuel is in this material? The fuel value is how much methane will be produced from a wet tonne of feedstock as it comes in the door. If you know how much gas you can produce, you can estimate whether it would generate enough revenue or savings to justify investing in a digester. The fuel value used for these calculations could be found in a five-minute exercise, looking at reference data to get a first estimate. Then, simple testing can begin to refine those estimates. Later, testing can extend all the way out to a six-week batch laboratory test, validating the initial estimates.

The next step looks at how much of what comes in will break down in a digester. There are a lot of organic materials that are not biodegradable. For example, wood chips, sawdust, and wood waste are natural and biodegrade in the forest. However, wood does not biodegrade in an anaerobic digester.

Also, consider the nutrition in the potential waste. Degradable food is not enough to make a great feedstock. While a digester can break down butter and ice cream, it would not be very healthy if that were all it was fed. Feedstocks with more nutrients can be valuable to your digester, depending on the situation.

Evaluating Feedstocks for Contamination

Like sewage, digester feedstocks are waste materials that can contain all sorts of trash or other material that the plant will need to manage. If it’s waste from a food factory, contamination can be rubber gloves, hair nets, and things that are in the food factory as part of the normal operation that occasionally end up on the floor. If it is vegetable or grease trap waste, there could be sand and gravel or metal nuts, bolts, and washers. Again, whatever got washed into the factory wastewater system can get to a digester. All this non-feedstock material is called contamination and finding uncontaminated feedstocks is important for municipal digesters to consider when accepting new waste.

The third type of contamination is chemical contamination. In a food factory, food safety trumps pretty much everything. Just as we might use bleach at home, there are other chemicals that are used in food factories to make sure that their tools and knives, and baking dishes are all clean and safe. But, everything they use to kill the bacteria in the food factory has the potential to kill the bacteria in a digester too. That’s where being aware of what goes on inside a food factory is important to understand the risk of contamination.

Conclusion

Using a biodigester to anaerobically codigest food waste at a sewage water resource recovery facility presents a promising solution for managing food waste and sewage solids, offering significant environmental and economic benefits. By diverting waste from landfills and increasing biogas production, municipalities can reduce greenhouse gas emissions, generate renewable energy, and create new revenue streams. To ensure the success of a codigestion project, it is crucial to carefully evaluate potential feedstocks. This evaluation involves assessing the biochemical benefits, fuel value, and seasonal availability of the feedstock, as well as understanding the impact on plant operations and the risk of contamination. By adopting a thorough screening process, stakeholders can maximize the utility of their existing assets and contribute to a cleaner, greener future.

As long as humans eat food and produce food waste, it needs to be managed in an economically and environmentally sound way. With quickly filling landfills, there is great potential for codigestion to become a larger part of organic waste management, reduce the amount of methane being released to the atmosphere, and tap into one of the only potentially carbon-negative fuels we have.

[1] https://www.w2ro.org/cpages/landfills#:~:text=Based%20on%20the%20current%20landfill,will%20be%20exhausted%20by%202028.

[2] https://bettergas.ca/images/uploads/standard_site/2024_RenewableGas_Infographic.pdf

This article originally appeared in the The Voice Magazine, published by the Ontario Society for Professional Engineers (OSPE).

Related Articles

Podcast: Codigestion Benefits and Considerations

Azura’s Dave Ellis was invited to join Anna Simet on the Biomass Magazine Podcast to talk about municipal codigestion. Municipal sewage sludge codigestion blends organic waste into existing anaerobic digesters to produce biogas and it is a great option to help reduce the carbon intensity of our fuel system. Listen to the Podcast.

Top 10 Things to Make Your Digester Biology Happy

Anaerobic digestion is a complex biological process that requires a great deal of nuance and subtlety to optimize its operation. This article looks at the 10 most critical aspects of AD and how to make them run for the best outcome. Read the full article.

Get Insights from the Bioprocess Experts Right to Your inbox

Sign up to the Discover Digesters Newsletter to access Azura’s best practices, field-tested advice, and insights into the anaerobic digestion & industrial wastewater treatment industries.

By submitting this form, you are consenting to receive marketing emails from: Azura Associates. You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact.