Introduction

Slips, Trips, and Falls are some of the most common workplace accidents, with biogas and RNG plants being no exception! The ever-changing characteristics of feedstocks, outdoor working areas, and digestate processing combine to create risks that might not be expected outside of anaerobic digester (AD) facilities. Three risk points we’ll touch on deal with slippery feedstocks, seasonal freezing risks, and slick polymer additives used in feedstock and digestate thickening and dewatering.

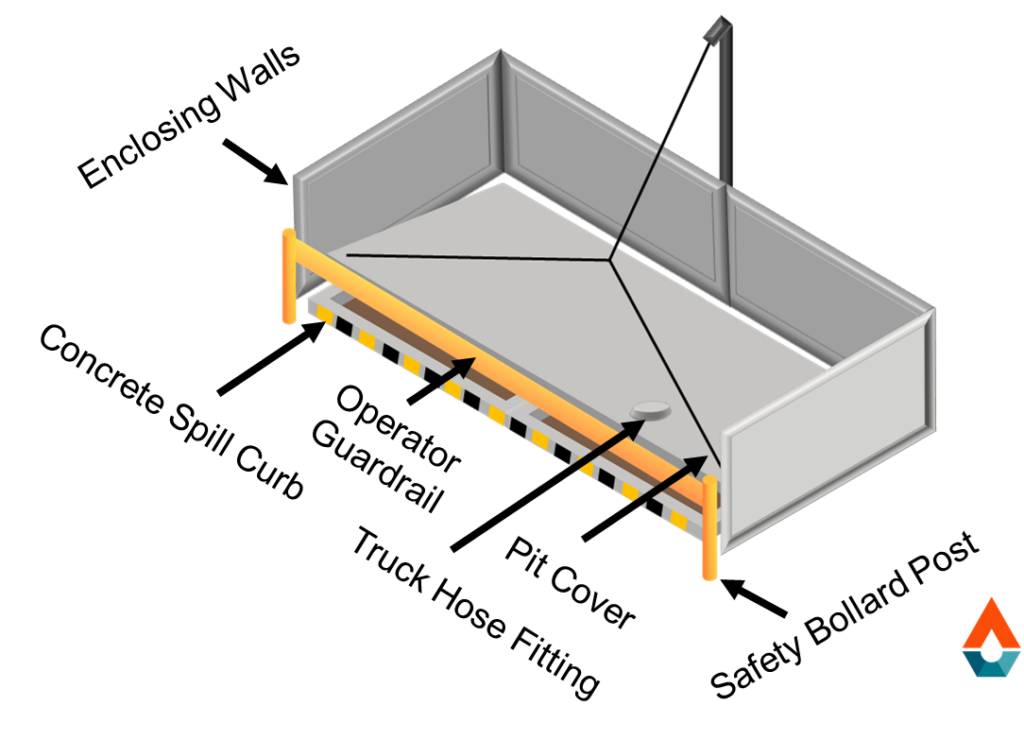

Slips Near the Feedstock Receiving Pit

Spills, splashes, and foaming around feedstock receiving pits can increase the risk of slips, trips, and falls. Food waste and other organic feedstocks that contain Fats, Oils, and Greases (FOGs) can be slippery and challenging to clean. Safety near the feedstock receiving pit is particularly important because of the risk of an operator slipping into the pit and potentially drowning. In a pit containing a thick layer of grease or foam floating on several meters of water, it can become physically impossible for a person to swim to the surface to breathe. Ways to reduce risk include: incorporating closing pit covers, spill curbs, guard rails, hoses to receive liquid waste, and good housekeeping practices.

Icy Patches

Puddles near access points or any walkway can become dangerous in the winter when they freeze. Apart from precipitation, puddles and ice patches form on vehicle areas, walkways, from snow melting off roofs, or above warm underground tanks. Frozen grease is even more slippery. Work areas such as those near access hatches, mixer motors, and pumps benefit from good drainage. To prevent slips on ice, design and construct floors and ceilings with positive slopes, drainage holes, non-slip design, and guardrails with kick-plates, as needed.

Polymer Storage, Make-down, and Feeding Systems

Certain food waste, OFMSW, and wastewater digester sites use a thickening or dewatering step for the raw feedstock or after the digester. Thickening and dewatering processes often use a chemical polymer which can be exceptionally slippery. Polymers can be stored as either a dry powder or liquid emulsion. Any damage to the stored dry chemical bags, emulsion drum, or liquid storage tanks can result in a slippery mess. Polymer spills are very difficult to clean up, and using a water hose just spreads the problem around. Designs that contain spills, use dry clean-up kits, and favor leak-proof equipment are preferred.

Conclusion

In anaerobic digestion, biogas, and RNG facilities, the variable and often slippery properties of feedstock combined with icy work areas and slippery polymer chemical use can increase the risk of slips and falls. Safety measures such as enclosures, good drainage, and leak-proof equipment can mitigate these risks. While these risks exist at other agricultural, food and beverage, waste, and wastewater facilities, AD facilities may look out for how these can compound and train workers accordingly.

*This article was first published in the BiogasWorld Safety Magazine.

Related Articles

Effectively Ensuring Safety in Biogas Facilities

Learn about five key categories of safety hazards and four hazard control methods within a biogas facility to better protect employees, the surrounding community, and our environment. Read the full article.

3 Unexpected Risks of H2S at RNG Plants

Explore three common scenarios where Hydrogen Sulfide can pose a threat in well-ventilated spaces and at well-maintained digester sites. Read the full article.

Get Insights from the Bioprocess Experts Right to Your inbox

Sign up to the Discover Digesters Newsletter to access Azura’s best practices, field-tested advice, and insights into the anaerobic digestion & industrial wastewater treatment industries.

By submitting this form, you are consenting to receive marketing emails from: Azura Associates. You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact.