Sudden hydrogen sulfide (H2S) spikes in your digester? In your feed tanks? One common culprit is feeding a large load of high protein feedstock too quickly.

Proteins naturally contain sulfur. During anaerobic digestion, some sulfur from the proteins are broken down and converted into dissolved sulfides and H2S gas. When too much protein is digested at once, the result can be a sizable release of H2S in the digester.

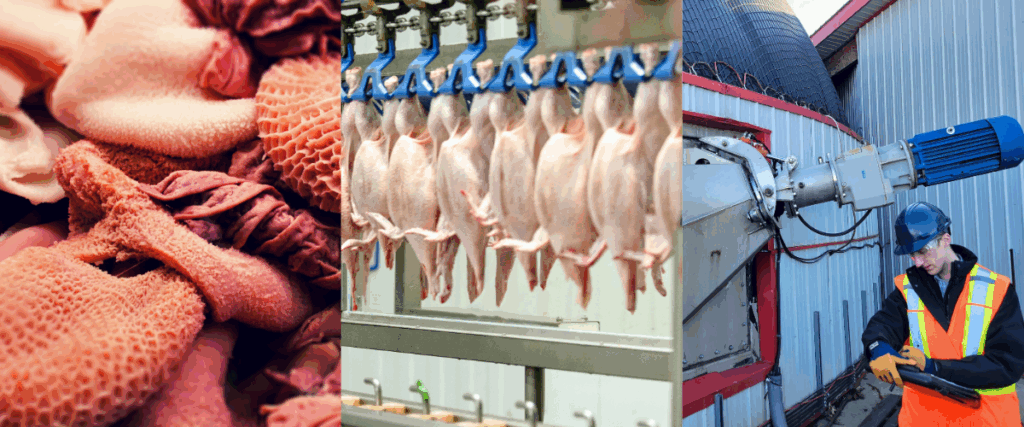

Examples of high protein feedstocks include:

- Meat processing waste like offal, blood, meal industry wastewater, etc.

- Whey from dairy processing.

- Spoiled meat from grocery stores.

To manage this risk:

- Introduce high-protein feedstocks gradually.

- Blend them with lower-protein feedstocks.

- Keep iron-based additives (e.g., ferric chloride, iron oxide, iron hydroxides) on hand to counteract H2S spikes.

While they carry higher H2S risk, high protein feedstocks often contain fats that have great fuel value and demand high tipping fees. Learn how to safely take advantage of their benefits by contacting Azura today.

*This article was first published in the Biogas World Project Showcase Report

Want a deep Dive on H2S?

Managing hydrogen sulfide (H2S) is critical for maintaining the biological health of your digester and the physical safety of your operators. This matters both inside your digester but also in your receiving and feed systems, and your end storage tanks too. In this video Azura’s Principal Engineer, David Ellis discusses the parameters that affect H2S and how to assess feedstocks to keep your digester running efficiently.

Download your own copy of Azura’s H2S Rainbow chart to see how pH and temperature can quickly change the H2S gas in your digester or feedstock tank.

Related Articles

Three Unexpected Risks of Hydrogen Sulfide at RNG Plants

Explore three common scenarios where H2S can pose a threat in well-ventilated spaces and at well-maintained digester sites. Read the full article.

Top 10 Things to Make Your Digester Biology Happy

Anaerobic digestion is a complex biological process that requires a great deal of nuance and subtlety to optimize its operation. This article looks at the 10 most critical aspects of AD and how to make them run for the best outcome. Read the full article.

Get Insights from the Bioprocess Experts Right to Your inbox

Sign up to the Discover Digesters Newsletter to access Azura’s best practices, field-tested advice, and insights into the anaerobic digestion & industrial wastewater treatment industries.

By submitting this form, you are consenting to receive marketing emails from: Azura Associates. You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact.